Buried polyethylene (PE) pipeline for gas

PE pipe for gas is the replacement product of traditional steel pipe and PVC gas. It should not only have good economy, but also have a series of advantages such as impact resistance, cracking resistance, aging resistance and corrosion resistance of stable and reliable interface materials compared with the traditional pipe.

Hotline : 0799-6796868

Product Details

Product features:

1. Corrosion resistance: PE is an inert material, which can resist the corrosion of various chemical media

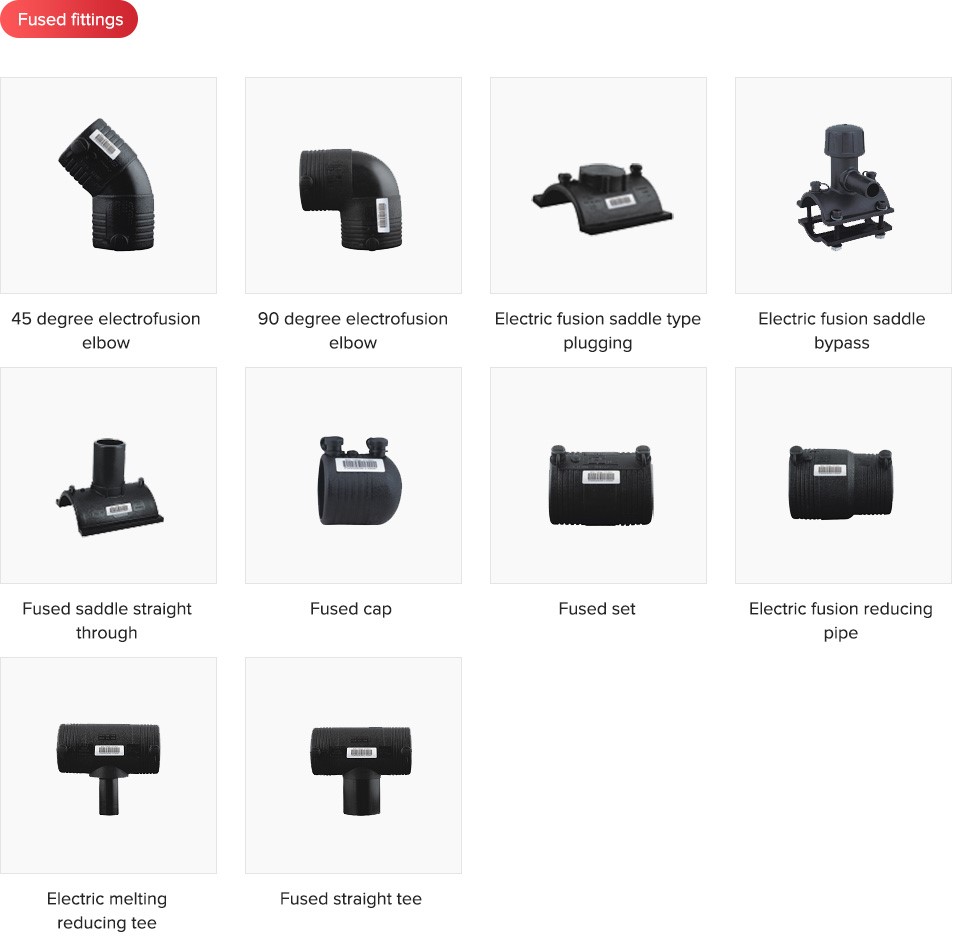

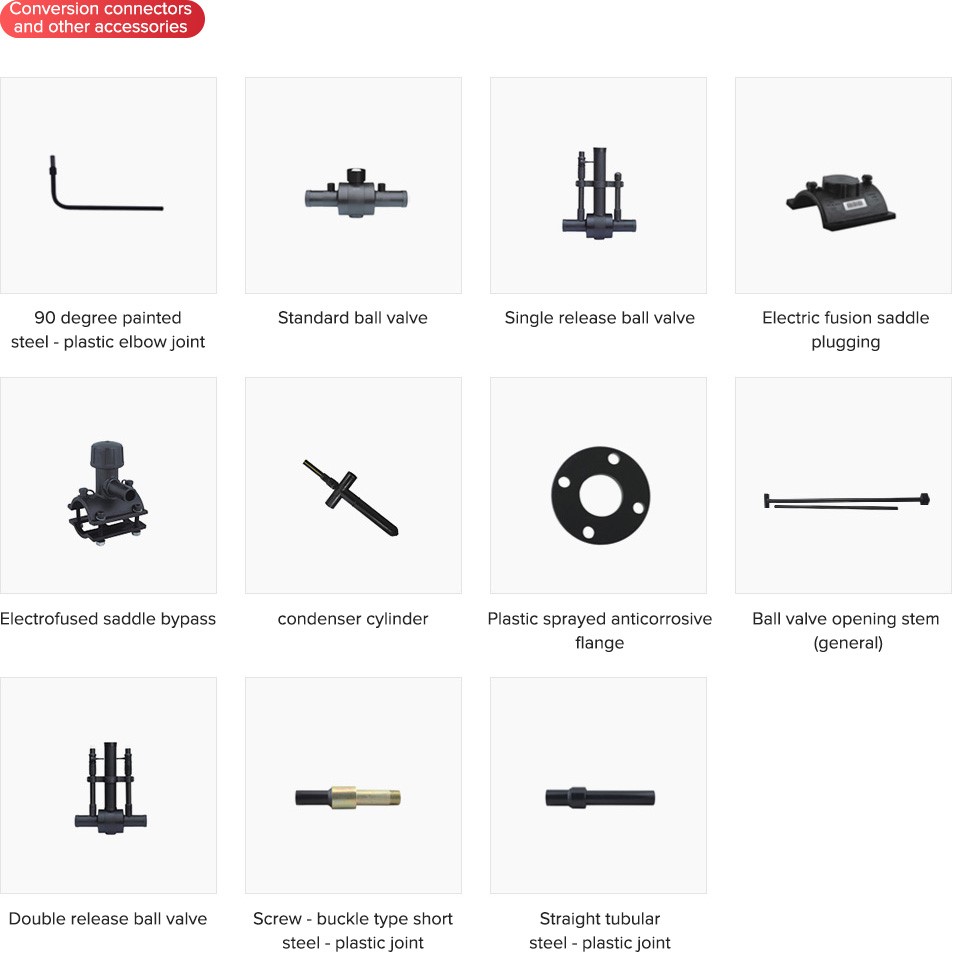

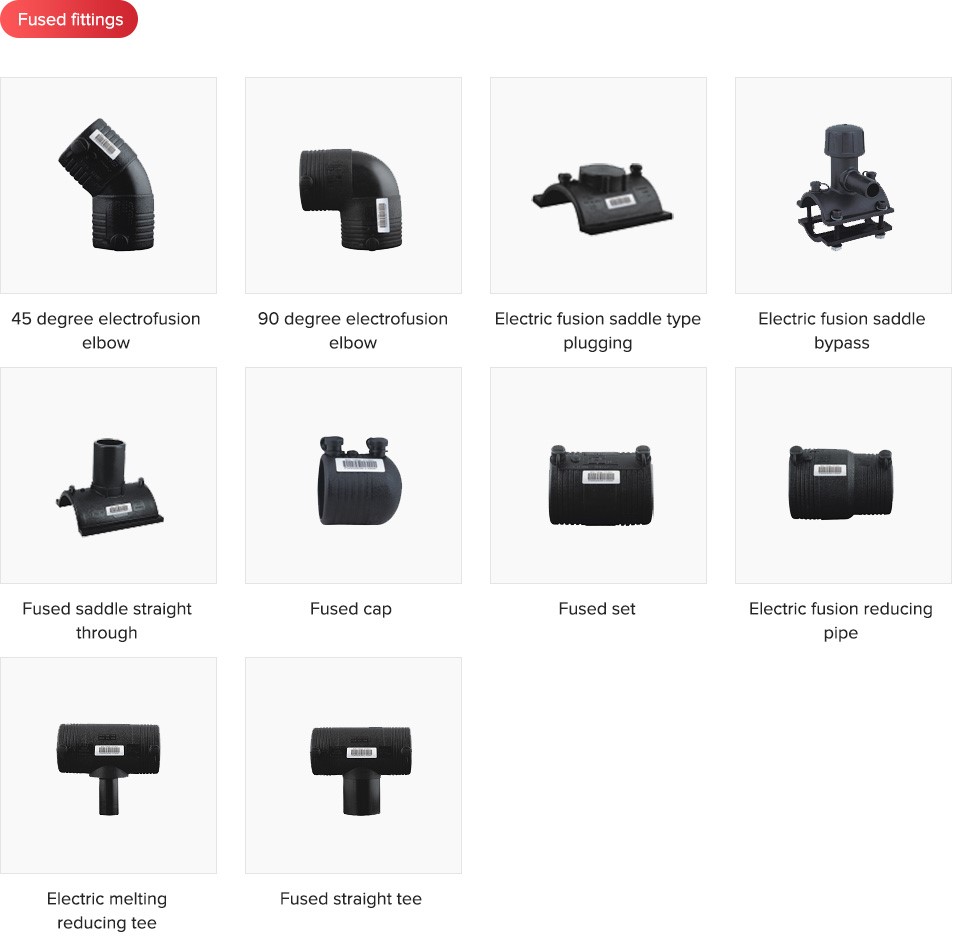

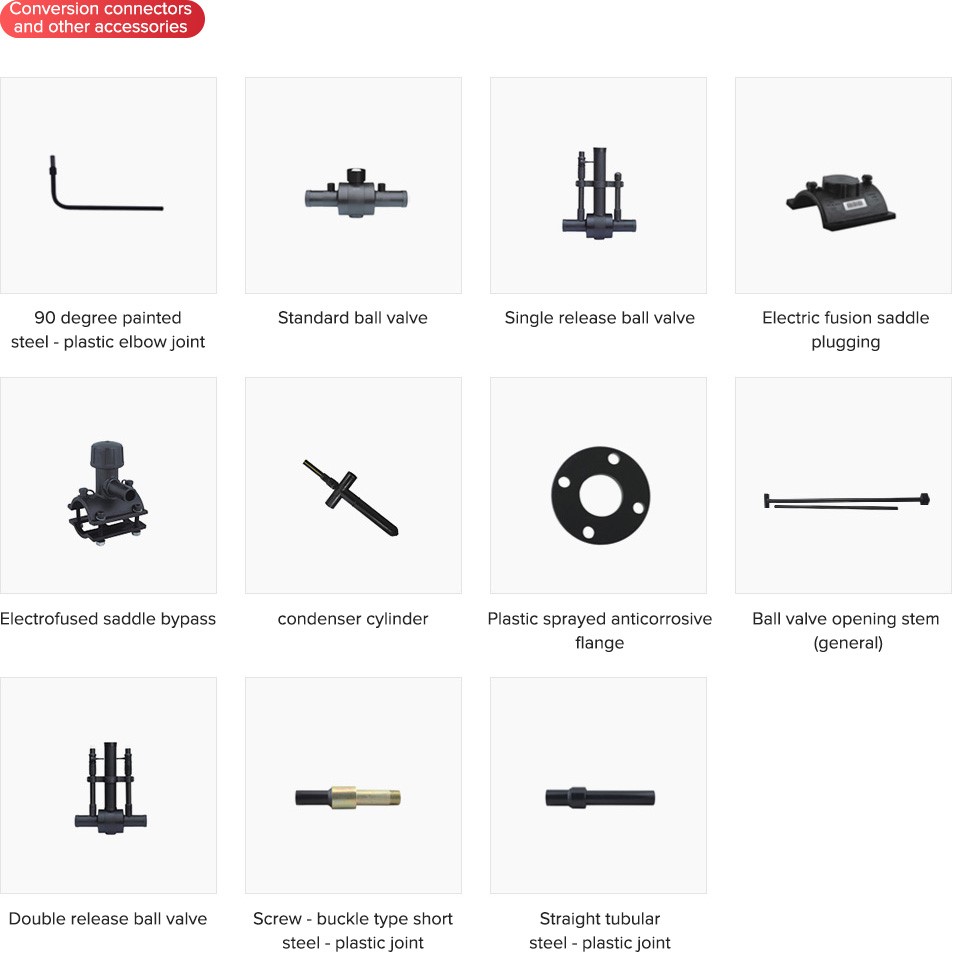

2. No leakage: PE adopts electric melting edge joint, hot melt butt joint and hot melt socket connection, and its interface strength is higher than that of pipe body

3. High toughness: the elongation at break of PE is generally more than 500%, which has strong adaptability to uneven settlement of pipe foundation and excellent seismic performance

4. Excellent resistance to slow crack growth (SCG) and rapid crack growth (RCP)

5. Excellent flexibility and scratch resistance

6. Good wear resistance, low friction coefficient of pipe wall, small flow resistance and strong conveying capacity

7. A variety of trenchless methods can be used, which greatly facilitates the construction and installation

8. The system cost is low and the maintenance cost is low, which can greatly reduce the engineering cost

Specification and model:

Implementation standard :GB 1558.1-2015

|

External Diameter dn

|

Nominal Wall Thickness en/mm

|

|

SDR11b

|

SDR17b

|

SDR21c

|

SDR26c

|

|

20

|

3.0

|

─

|

─

|

─

|

|

25

|

3.0

|

─

|

─

|

─

|

|

32

|

3.0

|

3.0

|

─

|

─

|

|

40

|

3.7

|

3.0

|

─

|

─

|

|

50

|

4.6

|

3.0

|

3.0

|

─

|

|

63

|

5.8

|

3.8

|

3.0

|

─

|

|

75

|

6.8

|

4.5

|

3.6

|

3.0

|

|

90

|

8.2

|

5.4

|

4.3

|

3.5

|

|

10

|

10.0

|

6.6

|

5.3

|

4.2

|

|

125

|

11.4

|

7.4

|

60.

|

4.8

|

|

140

|

12.7

|

8.3

|

6.7

|

5.4

|

|

160

|

14.6

|

9.5

|

7.7

|

6.2

|

|

180

|

16.4

|

10.7

|

8.6

|

6.9

|

|

200

|

18.2

|

11.9

|

9.6

|

7.7

|

|

225

|

20.5

|

13.4

|

10.8

|

8.6

|

|

250

|

22.7

|

14.8

|

11.9

|

9.6

|

|

280

|

25.4

|

16.6

|

13.4

|

10.7

|

|

315

|

28.6

|

18.7

|

15.0

|

12.1

|

|

355

|

32.2

|

21.1

|

16.9

|

13.6

|

|

400

|

36.4

|

23.7

|

19.1

|

15.3

|

|

450

|

40.9

|

26.7

|

21.5

|

17.2

|

|

500

|

45.5

|

29.7

|

23.9

|

19.1

|

|

560

|

50.9

|

33.2

|

26.7

|

21.4

|

|

630

|

57.3

|

37.4

|

30.0

|

24.1

|

Note: b as the first series

c SDR21 and SDR26 often used in trenchless gas pipeline repair

|

Location : Home > Products > PE Series

Location : Home > Products > PE Series