Hotline

0799-6796868

Location : Home > News > Company News

Location : Home > News > Company News

Facing the current severe economic situation, the staff of the technical department of Anyuan Pipeline Co., Ltd. actively expanded the space for innovation and efficiency, and through the company’s injection molding machine special-purpose AC servo system energy-saving and electromagnetic energy-saving transformation, it solved the problem of equipment aging and improved The qualified rate of the products has been improved, and the annual electricity bill has been saved nearly 1.5 million yuan.

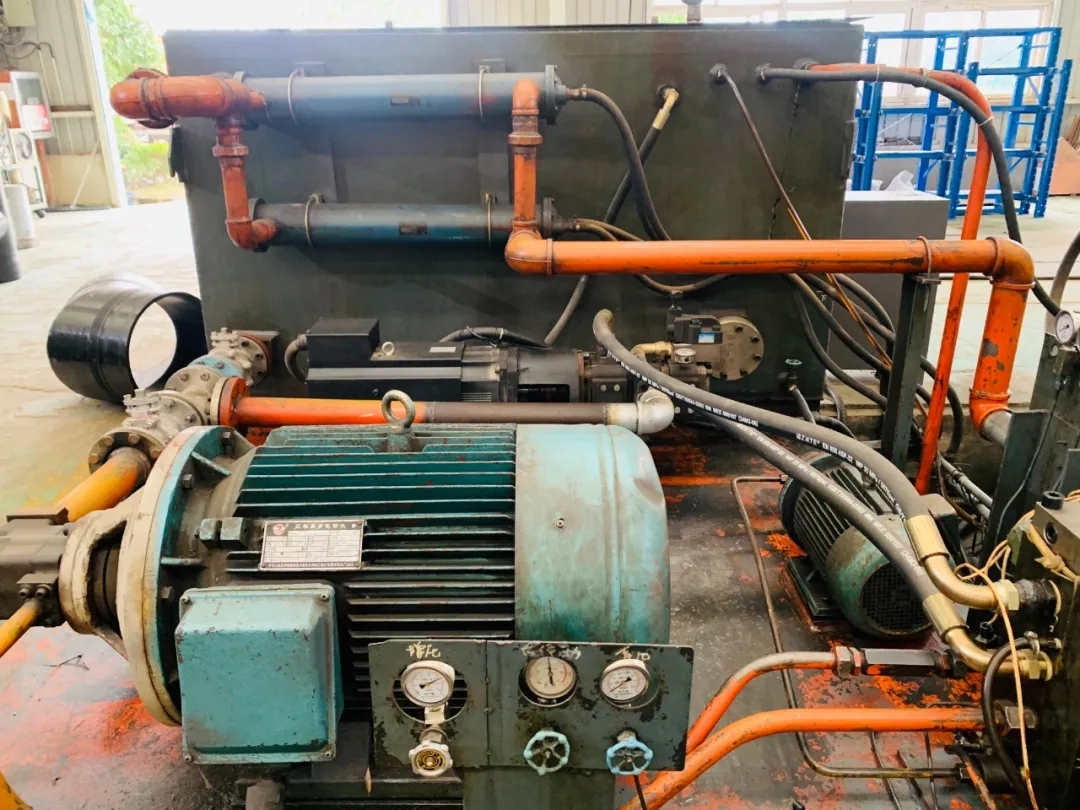

The company currently has 28 injection molding machines, which have been in operation for 19 years. The energy consumption of the hydraulic system of the traditional injection molding machine accounts for about 50% of the energy consumption of the whole machine. However, due to the long running time of the company's injection molding machine, the current energy consumption is high, and the service life of the hydraulic oil and oil seal is greatly reduced due to the high oil temperature. , The hydraulic system has frequent failures, which seriously affects the normal operation of the equipment, and the product cost remains high.

All of this, the company’s technical department personnel have seen and anxiously thought about "energy saving and consumption reduction". They actively discussed, went to the site, drawn drawings, and formulated measures, intending to make a fuss on the electromagnetic of the original injection molding machine. In the initial stage, they performed servo energy-saving transformations on the two injection molding machines, and measured electricity consumption before and after the transformation. They found that the hydraulic system energy consumption was reduced by 70-80%, and it could improve operating efficiency and reduce maintenance costs, but the energy consumption of the whole machine was still low. There is room for decline. Afterwards, they searched for a large amount of technical information and combined the original drawings, and finally formed a bold design improvement plan: transform the traditional stainless steel heater into electromagnetic heating.

But this means that there are certain risks when construction is carried out under normal production and orders. The team can only perform technical transformation on a staggered peak. Once, a production line was already over 10 o’clock in the evening when the day’s production task was completed. The technical reform team rushed to catch the time. As soon as the production line came to a standstill, it proceeded with transformation and debugging of various magnetic coils. This work continued until The debugging was successful only after 4 am the next day.

After countless days and nights of testing and debugging, this year, the company's 28 injection molding machine servo systems and electromagnetic energy-saving transformation have been completed, and the energy consumption of the whole machine has been reduced by 40%. In the past, the company's annual electricity consumption was more than 8 million yuan, of which injection molding machines accounted for 40%. After the transformation, nearly 1.5 million yuan of electricity can be saved throughout the year, and the product qualification rate is over 99%.

"Innovation is not big or small, and what can be used is a treasure." They used "small innovation" and reaped "big results", reflecting the infinite wisdom of the company's employees. "In the future, Anyuan Pipeline Company will also encourage employees to work together in mass technological innovation activities, come up with ideas, find ways, use their brains, and innovative thinking. Everyone's talents will eventually converge into a sea of wisdom. We will be committed to Through each item of "small results", promote the company's "big progress"." The company's responsible person said confidently.