Hotline

0799-6796868

Location : Home > News > Company News

Location : Home > News > Company NewsHe is the "start-up king" praised by everyone and the "head of the production workshop". After joining the factory for 18 years, he insisted on his beliefs, dedicated silently, and overcame difficulties in an ordinary post. He used his youth to interweave with the steel-framed warp and weft to set up a bright red banner. He is Wang Guangming, director of the production workshop of Anyuan Pipeline Company, the winner of the Jiangxi Province Model Worker in 2020.

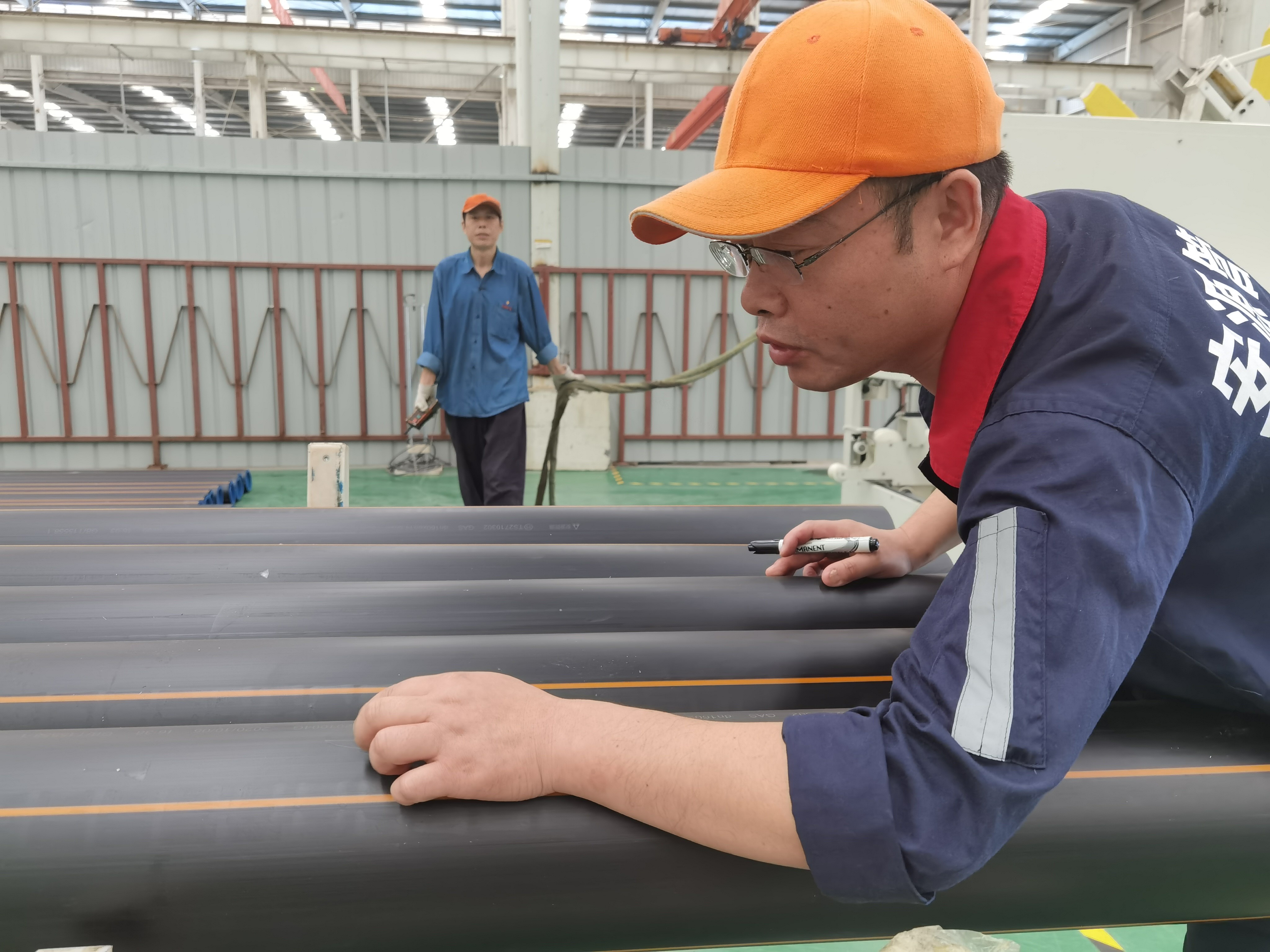

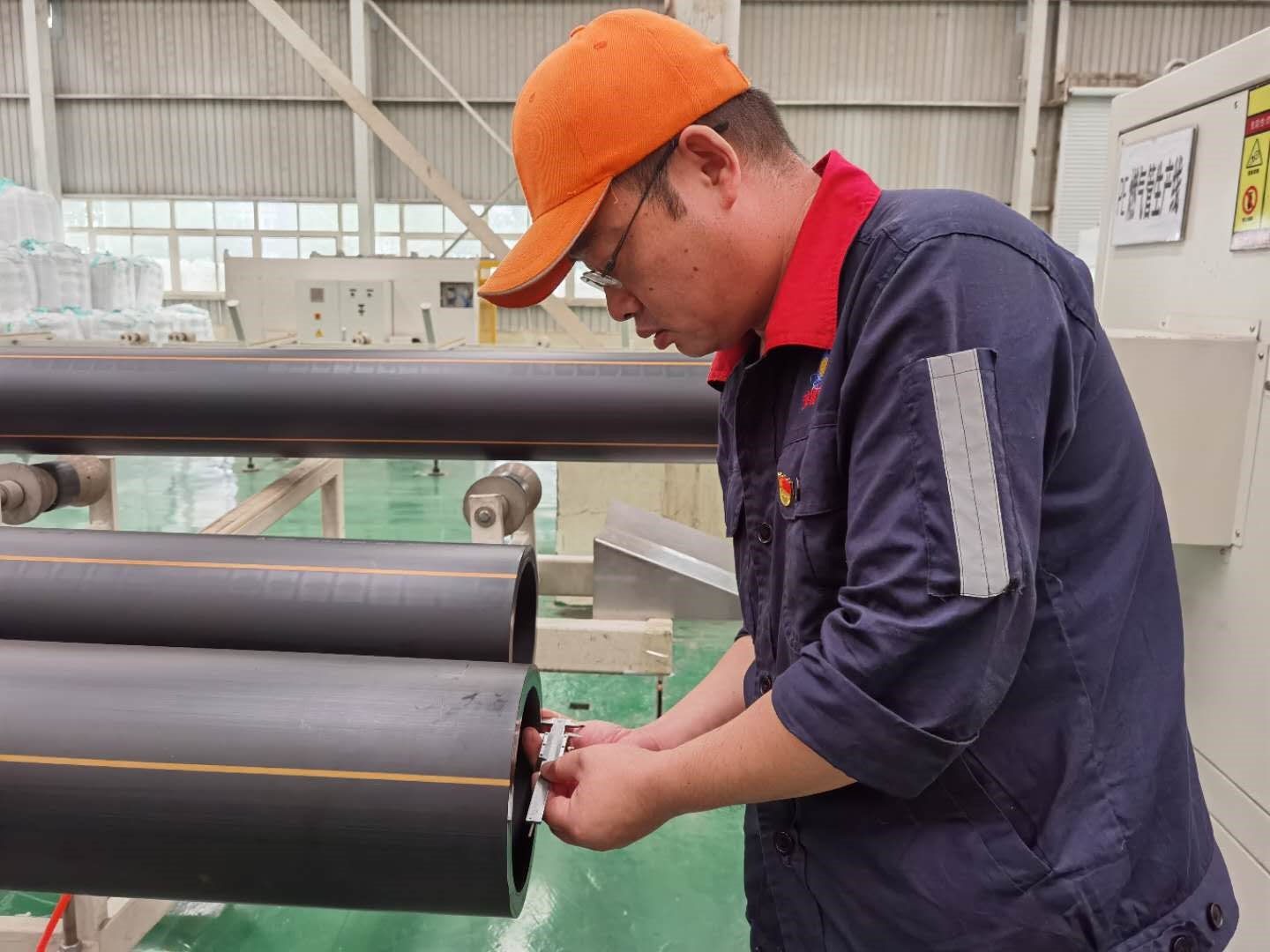

In February 2002, 30-year-old Wang Guangming came to Anyuan Pipeline Company from the third mining area of Gaokeng Coal Mine and became the first batch of employees of the company to participate in plant preparation and equipment commissioning and installation. Since entering the factory, Wang Guangming has always been on the front line of production. He started as an operator in the production workshop and was promoted to a craftsman, deputy director, and director. He has gradually grown into a model worker at all levels in the enterprise and an outstanding Communist Party member. "The King is Home". With the "craftsman spirit" of excellence and assiduous research, he has given himself the "18 martial arts". Every piece of equipment in the production workshop is his "heart and soul". What problems, how to prescribe the right medicine, and how to maintain it, he wouldn't have it. Everyone has a consensus: as long as Director Wang is there, there are no problems that cannot be solved. In 2019, during the trial production of PE pipes, he once went to the PE pipe workshop for routine inspections and found that DN315 was a bit deviated from the traction pipe. He found the technical consultant of the equipment manufacturer and quickly dealt with the problem. "Dr. Wang has very eyes. "Poison", we looked at a very normal place, as long as he "scanned", no small problem can escape." An employee in the production workshop said.

In safety work, Wang Guangming has always been selfless. At the beginning of the year, members of the production workshop team signed a safety commitment letter with employees, and strictly urged employees to work safely. Every day, the general meeting emphasized safe operation. Wang Guangming requires every operator to check whether the equipment safety mechanical lock and safety lever are normal, whether the mold opening and closing hydraulic pressure is normal, check whether the equipment temperature is normal when placing the product, and the working environment is safe before entering the mold area to work. Report problems in a timely manner and rectify them in time. At the same time, he asked the monitors of each class to make special reports on safety work with the operators at the shift meeting every day, and conduct a post inspection every 2 hours to check the product quality, operating environment and the working status of the employees; The monthly production workshop also organizes safety knowledge examinations, and should know and will meet examinations, and link the examination results with wages. If habitual offenders and third-violators cause minor safety problems, the first offender shall be given safety education, and the second offender shall be given financial punishment. From January to September, no safety accidents involving minor injuries or more occurred in the production workshop.

The introduction of the system focuses on implementation. He requires employees to conduct a regular "physical examination" for each pipe produced before it goes offline. Data such as wall thickness, external shaft size, out-of-roundness, internal and external finish, and steel frame distribution are controlled within the process requirements. According to the company's raw material evaluation regulations and workshop management methods, if a substandard product appears, a penalty of 1%-5% of the product price will be given, and appropriate rewards will be given to employees who have outstanding performance in cost saving. The rewards and penalties are distinct, which enhances the cost awareness of employees and improves product quality. Today, the yield rate of the production workshop has reached more than 99%, exceeding the company's target of 98%, and has become a benchmark in the industry. From January to September, more than 200,000 yuan of cost was saved.

Although the daily work is very busy, Wang Guangming did not stop studying. In the production of pipe fittings, the operator reported that the equipment was malfunctioning. After Wang Guangming learned of the problem, he took everyone to find out the cause, and found that it was because of the manual winding and the insufficient twisting of the electrofusion wiring post which caused the equipment to be unstable. According to the actual production, he proposed to use tin soldering to stabilize the resistance. As a result, the quality of the product increased from 98.5% to 99.2%. In one inspection, Wang Guangming found that the equipment was broken and there was a pile of wires, which caused great damage to the parts of the equipment. If the machine was shut down for maintenance, not only the processing time would be long, but the processing process would also be cumbersome. So he led the maintenance personnel to increase the equipment's wire-breaking and pile-up protection, which automatically shuts down when the wire is broken, which shortens the time for handling equipment failures and also increases the equipment operation rate. The company's flat seals are hand-polished, and the work efficiency is low, especially when processing the steel wire parts of the pipes, the quality is not guaranteed. Wang Guangming used lathes to improve tools, and the operators frequently praised him: "It's really fast and good!"

Wang Guangming uses dedication and exemplary spirit to "carefully polish every component and produce high-quality products", and has made outstanding contributions to the safety production, technological innovation, energy saving and consumption reduction of the enterprise. This time he won the provincial model worker award. He said that these belong to the common honor of more than 300 people in Anyuan Pipeline. In the future, they will go hand in hand with their families to add luster to the enterprise.